Here, you can see how many materials were planned. After the calculation is done, a report will appear.Step 2) System will take some time to calculate the material requirement. Input “1” in Create Purchase req which means for externally procured materials, MRP will generate purchase requisitions instead of planned orders.Īre you 100% sure that you really want to continue? If so, then again press enter.

Are you sure? If so, press enter.Įnter your manufacturing Plant code for which you want to take MRP run. The system asks you nicely to re-check your input parameter because the MRP run is going to reschedule and overwrite all existing data.

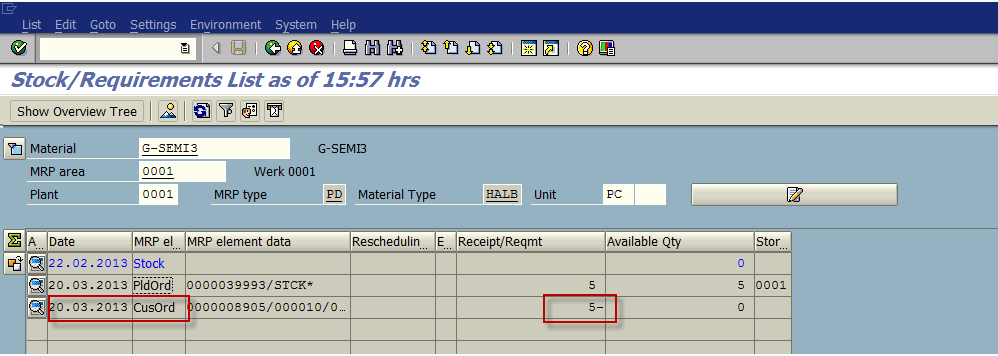

Enter Planning mode “3” as we will delete and recreate all planning data for all materials.Enter “1” in MRP List and system will create MRP list similar to stock /requirement list for later analysis of previous MRP run.Enter “3” for schedule lines which means MRP will generate schedule lines for raw materials having scheduling agreement.Which means for externally procured materials, MRP will generate purchase requisitions instead of planned orders. Enter Processing key as “NETCH” ( Net change in total horizon).Planning time fence (number of days starting from current date) is useful in case of MPS scenario where one can save the procurement proposals (planned orders) from undergoing any change since the last MRP run.Įnter your manufacturing Plant for which you want to take MRP run.Basically, it ensures the availability of the critical resources, which should not hamper the production by maintaining the stock.A separate run occurs for the MPS items they are not included in the MRP run.It is used specifically for critical materials usually high valued products where you do not want changes in your production plan within planning time fence in next MPS run, and production plan gets firmed automatically as soon as it comes within planning time fence unlike MRP run. If, you don’t want to run MRP on the material then MRP type “ND” can be maintained in the material master. MRP type “PD” in material master MRP 1 view is essential to run the MRP for the materials.

Production orders or Purchase orders are created after conversion of planned orders and purchase requisition respectively.

0 kommentar(er)

0 kommentar(er)